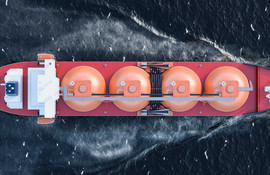

As the demand for energy and Liquefied Natural Gas (LNG) increases worldwide to fuel economic growth, suppliers of LNG face many challenges getting to first liquids, meeting local codes and regulations, maintaining and improving reliability, and accessing qualified human resources for everything from engineering to plant operation.

Automating a LNG terminal involves people, experience and integration of field instrumentation, accurate measurement, custody transfer, analytics, safety, security, training, process control, asset management, and business systems.